▷ Reduced wall thickness for thin-wall packaging - ENGEL Blog

By A Mystery Man Writer

Reduced wall thickness for thin-wall packaging ✓ Which challenges the developments place on the injection moulding process ➠ Read more

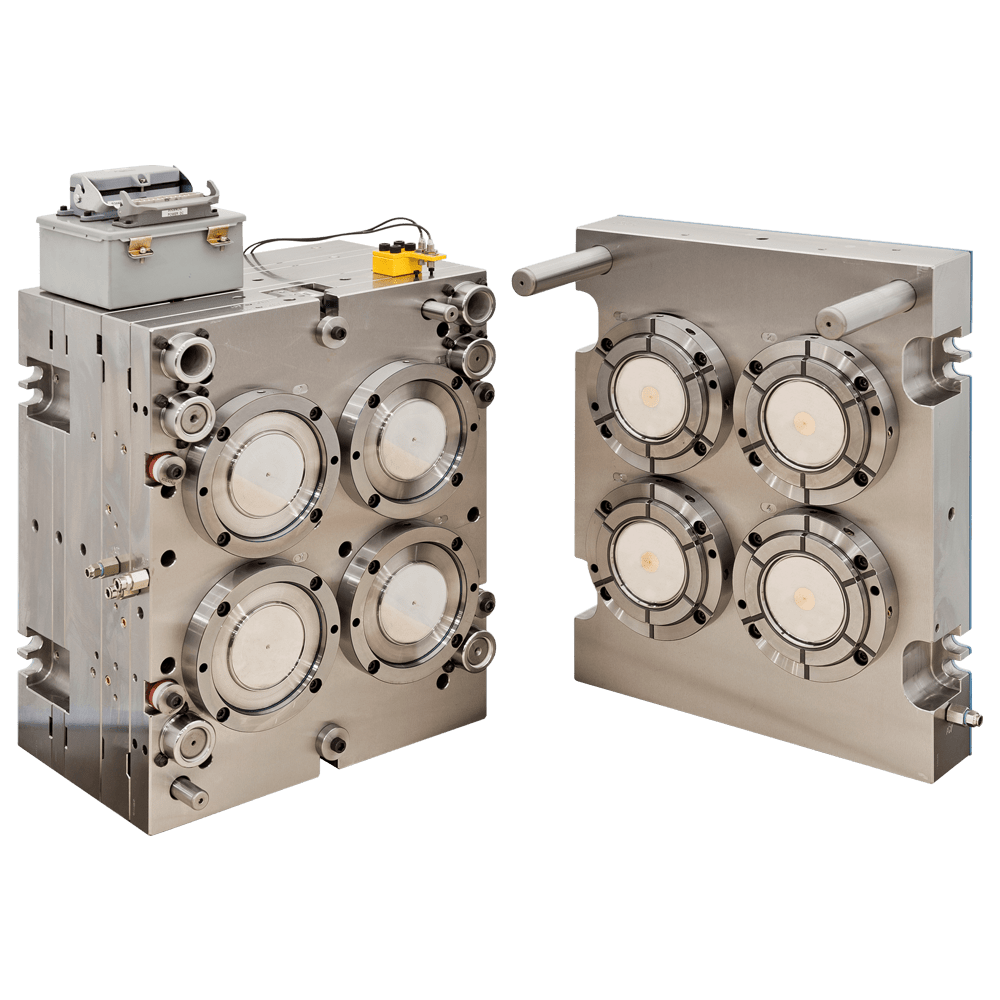

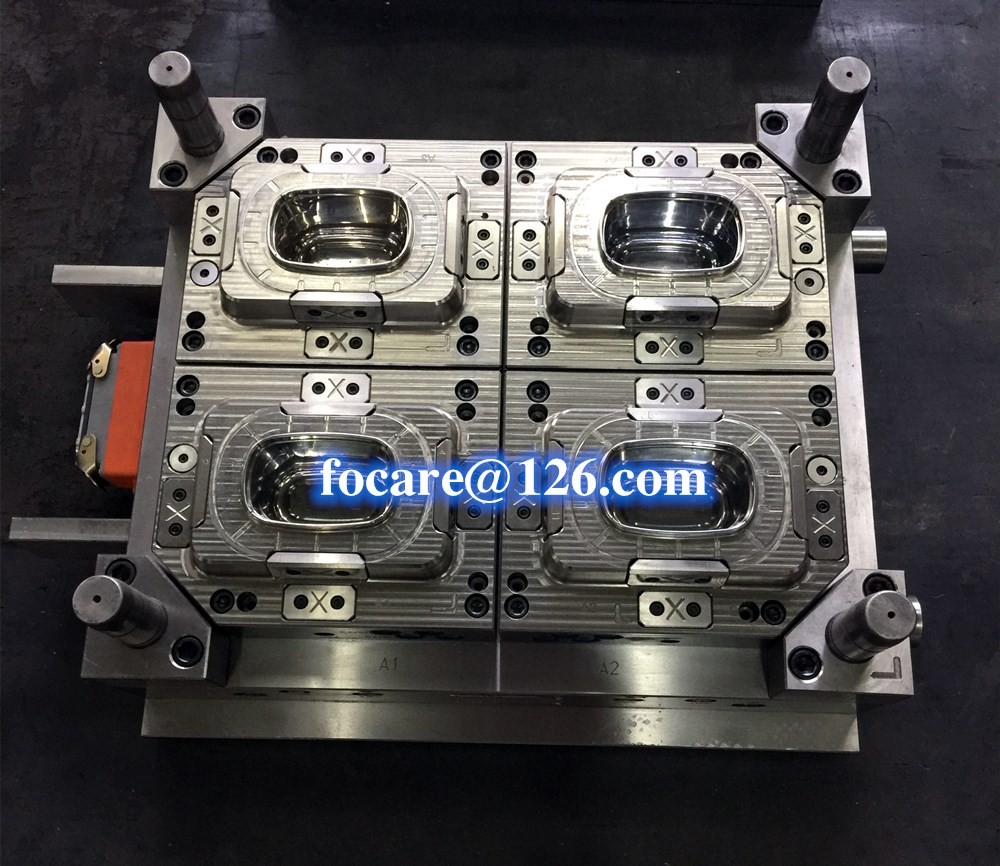

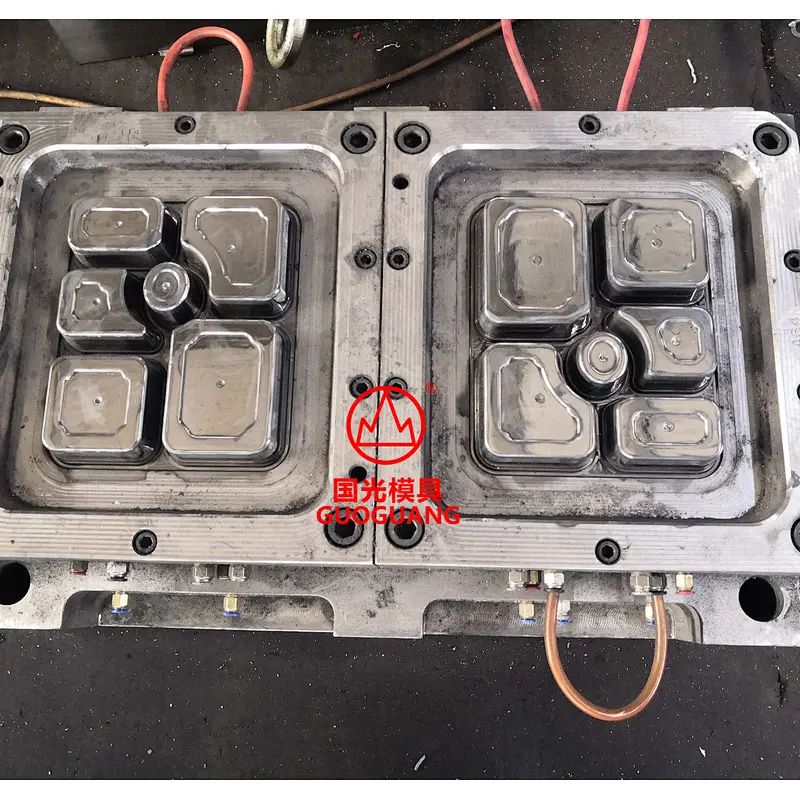

The ever-advancing weight reduction of packaging through reduced wall-thickness is an ongoing topic in the packaging industry, which is constantly increasing the demands on injection moulding machines.

Minimum Wall Thickness for 3D Printing

)

▷ Solutions for thin wall injection moulding - ENGEL

▷ Production of plastic packaging - ENGEL

)

▷ Injection molding process for lightweight parts - ENGEL

)

▷ Injection moulding machine for thin-wall plastic - ENGEL

)

▷ Injection molding process for lightweight parts - ENGEL

)

▷ Solutions for thin wall injection moulding - ENGEL

▷ Reduced wall thickness for thin-wall packaging - ENGEL Blog

▷ Stable processes with iQ weight control - ENGEL Blog

Recommended Wall Thickness for 3D Printing

ENGEL and partners develop single injection moulding process for

- Thin Wall Injection Molding Solutions

- Thin wall plastic container mould - Moldman Precisions

- Thin Wall Disposable Plastic Cutlery Mold Factory and Manufacturers - Made in China - Odin Mould

- Thin wall transparent food container mold, ice cream box thin wall

- China Plastic injection mold of thin wall microwave packaging box,disposable food packaging container mold Manufacturer and Supplier

- Floral Butterfly Pattern

- Buy Jockey 1487 Women's Combed Cotton Rib Camisole with Adjustable Straps-Nude online

- Women Wear White Pants Stained With Menstrual Blood To Make Feminist Statement - Guerrilla Blog

- Outdoor Voices Moisture Wicking Women's Hiking Leggings

- Buy Avia Clothing Online In India - India

- Aim'n Reflective Shaping Tights - AirRobe

- Under Armour HeatGear Armour Leggings (White)-1289577-100

- Distressed Denim Look Flag SOFT Capri Leggings July 4th Independence Day Red White Blue Capris rts

- 13,089 Teen Bikini Images, Stock Photos, 3D objects, & Vectors

- Kilo Tango - Women's Golf Apparel