Temperature contour (a) Goldak Double Ellipsoidal (b) Conical (c) CCC

By A Mystery Man Writer

PDF) Simulation and experiment on residual stress and deflection of cruciform welded joints

Temperature contour (a) Goldak Double Ellipsoidal (b) Conical (c) CCC

M. VASUDEVAN, Head, Advanced Welding Processes and Modeling Section, B.E, M.E, PhD, Indira Gandhi Centre for Atomic Research, Chennai, IGCAR, Metallurgy and Materials group (MMG)

Thermal and velocity fields at xy face for 200A (a) 50 ppm (b) 150 ppm

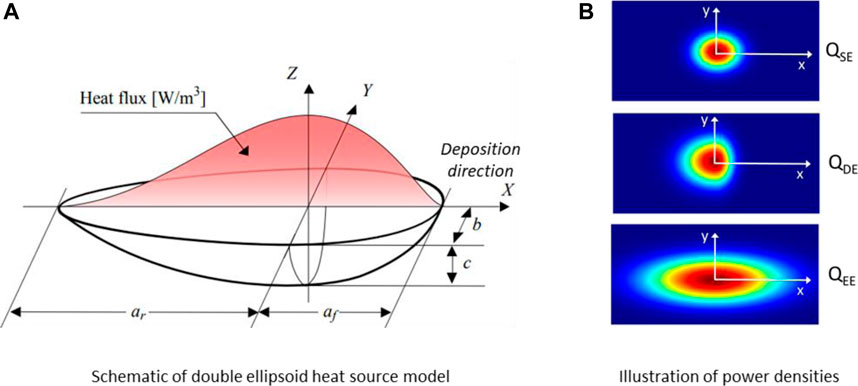

Extension of the double-ellipsoidal heat source model to narrow-groove and keyhole weld configurations - ScienceDirect

PDF) Determination of heat source model for simulating full penetration laser welding of 316 LN stainless steel by computational fluid dynamics

Thermal and velocity fields at xy face for 300A (a) 50 ppm (b) 150 ppm

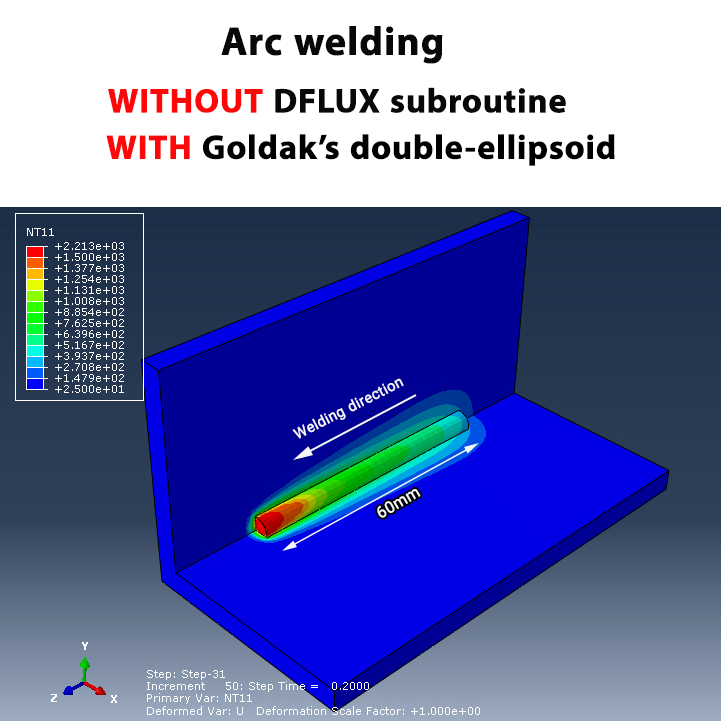

Simulation set up showing welding coordinate system and boundary

Simulation Arc welding using the Goldak's double-ellipsoid heat source model Abaqus – Abaqus Tutorials

Frontiers Development of an Elongated Ellipsoid Heat Source Model to Reduce Computation Time for Directed Energy Deposition Process

Metals, Free Full-Text

M. VASUDEVAN, Head, Advanced Welding Processes and Modeling Section, B.E, M.E, PhD, Indira Gandhi Centre for Atomic Research, Chennai, IGCAR, Metallurgy and Materials group (MMG)

- Listen To E-40's Double-Disc Album, The D-Boy Diary

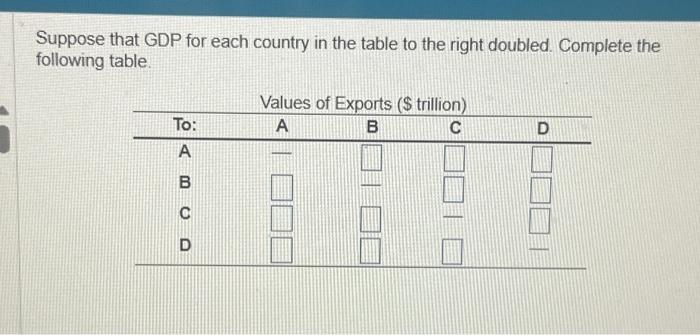

- Solved \begin{tabular}{ccc} Country & of World S̈pending

- 27 Inch Wide Accessible ADA - Double Door Base Cabinet - Luxor White Shaker - Ready To Assemble, 27W x 32.5H x 24D

- Study visit schedule. BSAP body surface area percentage, CCC

- Yotes Game Day on X: MBB #3 @YotesHoops defeats Northwest 103-60 in the CCC Quarterfinals. Five different Yotes scored in double figures; Jake O'Neil added another double-double to his career with

- Wacoal Sport Bra 34G Underwire Convertible Straps Molded Cups Athletic Workout

- Baby Be Mine Mommy & Me Delivery Robe with Matching Baby Receiving Gown & Hat Set

- Ultra Lift Medical Spa Chair - Michele Pelafas

- FINETOO 6 Pack Cotton Underwear for Women Cheeky High Cut Breathable Hipster Bikini Striped Panties Pack S-XL

- Duluth X-Back Tall Clip Suspenders